Modern whole milk management at Agrarprodukt Sonneberg

23. Dezember 2021 — General Information, Pasteurising, Products, Calf feeders — #Work management #CalfExpert #DoubleJug #Installation #Management #MediumFrame #MilkTaxi #Pasteurising #Practice report #Calf feeder #Whole milkHealthy whole milk for the calves using a milking robot, MediumFrame Pasteur and CalfExpert

The Agroprodukt Sonneberg cooperative is located in the south of Thuringia, close to the Bavarian border. Approximately 2,600-2,700 animals are kept on the farm. That is about 1,300 lactating cows and their offspring. The cooperative employs a total of about 90 people.

This article is about

Collecting and storing whole milk

Newly milking cows at the Sonneberg Agroprodukt cooperative are milked by two DeLaval milking robots. The colostrum is collected separately in a MilkTaxi during the first 2-3 days and fed to the young calves as mixed colostrum. The remaining milk is transferred to a storage tank, where it is cooled. This whole milk, which is not sent to the dairy, is intended for feeding the calves.

Together with the farm manager Mr Ehrlicher, the herd manager Ms Fischer and our partner Melktechnik Lauterbach, we came up with the following concept and put it into practice:

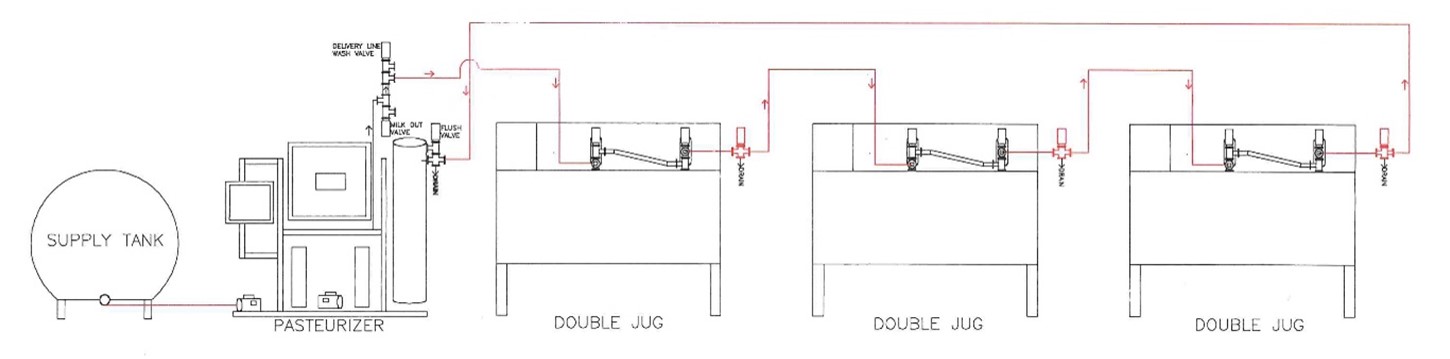

The new reproduction barn is located directly next to the new calf barn. Nevertheless, there is still a distance of several metres between the storage tank and the MediumFrame continuous pasteuriser, which is located in the calf barn's service room. A lift pump on the storage tank transports the milk via pipes below the roof to the neighbouring barn.

The MediumFrame pasteuriser

The milk is pasteurised in the calf kitchen of the calf house in the MediumFrame pasteuriser using the fast method (73 °C at 15 seconds holding time). This "flash method" is already very energy-efficient, since the warm milk preheats the cold milk flowing in after pasteurisation in a heat exchanger. However, the MediumFrame model at Agroprodukt Sonneberg has an additional special feature: in addition to the heating element, which is operated by an electric boiler, there is a heat exchanger that is supplied with surplus hot water from the farm's biogas plant. The pasteuriser can manage with virtually no additional electrical heating energy if there is sufficient biogas heat.

The CalfExpert and DoubleJug

The pasteurised milk is fed in two ways:

- Via MilkTaxis where the milk can be filled at the desired drinking temperature. This is then the milk for the calves in their second week of life, which is fed in the individual stalls.

- Via a pipe system to the DoubleJug storage tanks on the CalfExpert feeders.

The previous H&L 100 feeders on this farm could only feed milk replacer (CMR). The three new CalfExpert feeders provide the variability to feed whole milk and CMR.

Given the large number of calves, the whole milk is not sufficient to supply all the animals. This is why we have adjusted the feeding curves on the CalfExpert to slowly switch the calves to CMR in the second half of the milk-feeding phase.

The DoubleJug milk tanks consist of two milk chambers. The CalfExpert draws milk from one tank and switches to the second tank when the first tank is empty. Then a cleaning cycle begins and the empty tank can be refilled at any time.

Cleaning and hygiene

The long milk pipes on the farm were a challenge. Approximately 300 m of milk pipes were installed in the 100 m long calf barn. The MediumFrame handles the cleaning of these pipes to the DoubleJugs. Milk residues are blown out into the DoubleJugs by air pressure to avoid them remaining in the pipes Subsequently, not only the pasteuriser itself is cleaned, but also all connected milk pipes.

To sum up, it is safe to say that the new system of whole milk feeding at Agroprodukt Sonneberg is the first of its kind in Europe so far. It is the most advanced way of feeding whole milk to calves in a safe and performance-enhancing way.

pasteurisation of the whole milk in the MediumFrame continuous pasteuriser and subsequent feeding via 3 CalfExpert automatic feeders with DoubleJug milk tanks.

pasteurisation of the whole milk in the MediumFrame continuous pasteuriser and subsequent feeding via 3 CalfExpert automatic feeders with DoubleJug milk tanks.