Pasteurising

Mastitis bacteria play an important role in illnesses in the calf pen too. Pasteurisation eliminates up to 99.5% of these bacteria.

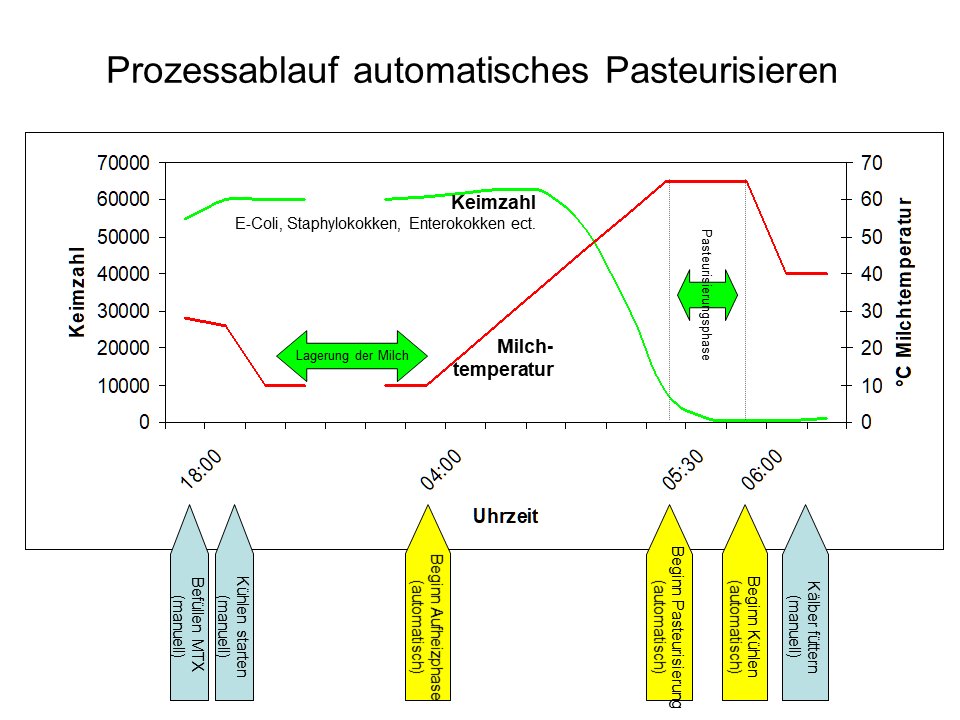

Pasteurisation function

Pasteurising at a temperature of 63 °C for 35 minutes using the batch method destroys 99.5 % of the dangerous pathogens. As an alternative to this programme, the MilkTaxi offers two different heat treatment methods at 60 °C for 60 or 70 minutes. All the starting times can be freely programmed. The result is that the milk has already been pasteurised when you arrive in the barn for feeding in the morning.

Automatic cooling function

Water cooling comes as standard with the MilkTaxi pasteuriser. This allows the milk to be stored fresh until feeding or pasteurising. The automatic cooling programmes are particularly practical when robotic milkers are used. It records the fill level and temperature for automatic filling. In addition, the cooling process is programmed in such a way that it makes optimum use of the required energy.

Hot-water heating

Save electrical heating energy by feeding your surplus hot water – for example from a biogas plant or from heat recovery – into the cooling jacket of the MilkTaxi. This warms the calf milk without incurring additional energy costs. The MilkTaxi measures and controls the temperature automatically.