Whole milk management

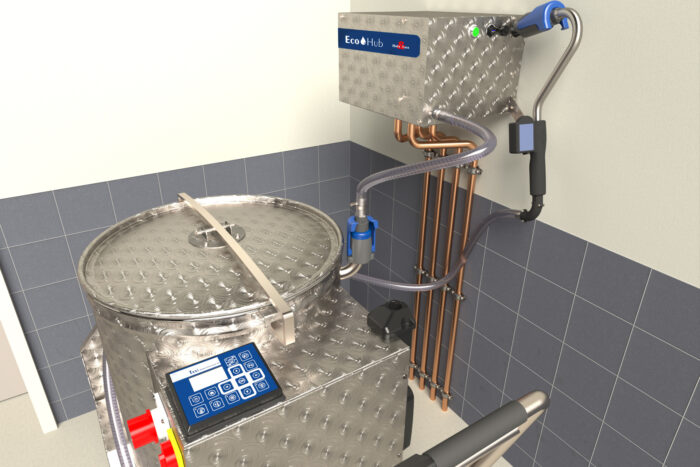

Our EcoHub external heat exchanger makes heating and cooling so easy. The Automatic Milk Supply helps with whole milk logistics.

EcoHub uses renewable energy sources and allows water to be recycled for cooling and heating in all MilkTaxi models 3.0 and 4.0.

Retrofit solution for sustainable milk preparation

A conventional MilkTaxi with a pasteurisation function uses a very simple water cooling technique, but it has disadvantages in terms of sustainability and efficiency, because the water used for this purpose is not recycled. Moreover, cooling is ineffective with small quantities. There is also no way of converting a MilkTaxi to a pasteuriser; a completely new unit would need to be purchased. EcoHub offers a flexible solution for cooling, pasteurisation and hot water use without having to replace equipment. EcoHub is easy to retrofit to all generation 3.0 or 4.0 MilkTaxi models from 2015 onwards.

How does the EcoHub work?

The EcoHub uses up to two different sources of water, such as normal tap water, pre-cooled ice water or hot water from biogas plants, to achieve the optimum temperature for milk. It also features a heat exchanger coil that allows small quantities of milk to be heated to the desired temperature and milk from milking robots to be used directly (see EcoHubAMS with AutomaticMilkSupply). A wireless connection ensures cable-free communication for heating and cooling processes.

The AutomaticMilkSupply (AMS) controls the storage of calf milk separated off by milking robots in a milk cooling tank. As soon as the MilkTaxi needs milk, the required amount is pumped into the Milk Taxi.

Automatic calf management

The AMS optimises the storage and management of calf milk set aside by milking robots by safely directing it to a cooling tank until the MilkTaxi requests the milk for feeding. Just before the pasteurisation process, the Milk Taxi sends information about the required quantity of milk to the AMS control unit. The AMS then pumps the corresponding quantity into the MilkTaxi. Communication is effected over a wireless connection. The AMS is independent of robots and requires only one rinsing signal to distinguish between milk and water.

Cleaning the AMS

The separation line is cleaned automatically by the robot. When the cooling tank is cleaned manually, any milk that accumulates during the process can be diverted into buckets.

The AMS intelligent milk management function can also be combined with the EcoHub heat exchanger. Together, this gives rise to the ‘EcoHubAMS’ solution.

Maximum utilisation of in-house resources

EcoHubAMS not only ensures that non-marketable milk is put to good use, but also allows renewable energy to be used. As a result, a farm can make a major contribution to protecting the climate while also saving money.

Shared technology saves investment costs

With EcoHubAMS, one circuit board controls both processes, managing the milk supply from the milking robot and controlling the use of the heating and cooling systems with local sources of water. Not only does this add real value to your work processes, but it also means lower investment costs for you as a customer.